"GhostZ" (GhostZ)

"GhostZ" (GhostZ)

09/07/2013 at 13:18 • Filed to: V8s, technical, ask oppo, GhostZ

0

0

64

64

"GhostZ" (GhostZ)

"GhostZ" (GhostZ)

09/07/2013 at 13:18 • Filed to: V8s, technical, ask oppo, GhostZ |  0 0

|  64 64 |

Teach me about rod/stroke ratio, bearing types and strengths, crank/piston/rod material strength, and the relationships between piston velocity (mean and peak) and piston acceleration.

Does increasing the bore of the engine cause more stress on the reciprocating parts, outside of them being heavier? Which is better, lighter, weaker components, or stronger ones? Which is the limiting factor?

The firing order of a cross-plane crank makes manifold tuning supposedly difficult. Explain how this could be a problem at over, say, 7000 RPM, or does it become less of a problem?

What type of camshafts are best for 7000+ RPM? Solid rollers? What is "valve lash"? Does higher RPM mean more lift is needed to, or just more duration?

Do carburetors actually work better at sustained high RPMs than fuel injection (aka, why Nascar uses them)? Or is this a myth? What about for track use?

Can a 2-bolt main block be converted to a 4-bolt main?

Which saps more power: added weight of a longer stroke, or added friction of a proportionally higher RPM?

What are the primary differences that let race (circle track) engines sustain high RPMs vs street engines that stay primarily in the low RPMs?

How does a turbo or supercharger affect stress on high RPM motors? Is more-boost-less-RPM worse, or less-boost-more-RPM worse?

Does a tall deck height become a problem if you don't need the long stroke?

Why:

Let's say I want a good V8 engine with 8500-9000rpm shifts. I want to make peak power between 7500 and 8500. Don't ask why. Just go along with it.

My options are:

Ford:

1. Ford 302 Mexican Block (4" bore, 3" stroke, short rods, short deck)

2. Ford 289 "Hi-Po" (4" bore, 2.87" stroke, slightly longer rods)

3. Ford 351W (4" bore, 3.5" stroke, long rod, tall deck, stronger mains)

4. Ford 460 (4.36 bore, 3.85" stroke, extremely tall deck)

5. Ford 429 (4.36 bore, 3.59" stroke, basically the same as the 460)

Mopar:

1. Chrysler RB Block (extremely tall deck, 3.75 stroke, 4.14 (383) to 4.25 (426) bore)

2. Chrysler B Block (3.375 stroke, shorter deck (but larger than 351W), 3.889 (313) to 4.14 (393) bore)

3. Chrysler LA Block (3.31" stroke, smaller bore spacing, 3.91" (318) to 4.04" (340)

In trying to go for short-stroke-wide-bore-highest-safe-RPM build possible. Ignore the amount of power the engine could put out and go just for the "character" of the engine.

Any good GM motors (I know the least about them) that I should add to the list?

Right now it looks like a 289 Hi-Po block, or a 302 with a 289 crank, would be the place to start, but it also looks like that would yield the least power for the RPMs. Also, since it's the smallest engine of the group, would it actually be worse since more parts would need beefed up to handle the speed?

For example, and RB block may have a longer stroke, but if the engine parts are stronger, not just heavier, could it take the same RPM and have a larger displacement?

TheLOUDMUSIC- Put it in H!

> GhostZ

TheLOUDMUSIC- Put it in H!

> GhostZ

09/07/2013 at 13:26 |

|

I'd build me a Chevy 302, with Ti rods and a solid roller cam. A Chevy 302 is a 327 block with a 283 crank. Although, a v8 that revs that high at all will barely be streetable.

GhostZ

> TheLOUDMUSIC- Put it in H!

GhostZ

> TheLOUDMUSIC- Put it in H!

09/07/2013 at 13:32 |

|

"streetable" is a relative term. Small diameter tires, proper rear end gears, a proper exhaust and a really light weight body (ha, you thought I would put this in a muscle car?) means that it would have plenty of low end torque to move around, and once untapped around 6000-7000 rpm could scream. I can't imagine it being worse than V-TEC or turbo lag. Or are there low-rpm reliability issues?

Getting ahold of a 327 easily seems difficult. And what advantage does it have over the much-cheaper ford 302? Different mains, better rod/stroke ratio?

BugEyedBimmer - back in the Saddle Dakota Leather

> TheLOUDMUSIC- Put it in H!

BugEyedBimmer - back in the Saddle Dakota Leather

> TheLOUDMUSIC- Put it in H!

09/07/2013 at 13:34 |

|

BMW and Audi would like a word with you. And the LS7 said to tell you it's knocking on that door too.

pdthedeuce

> GhostZ

pdthedeuce

> GhostZ

09/07/2013 at 13:35 |

|

wow , lots of question , but I can help with a few . the ONLY cam you should use for those rpms would be a solid roller cam. hydraulics don't like to rev that high .Nascar no longer uses carbs . I believe some blocks can be converted to 4 bolt mains, but it's better if you start with one . for high rpms , you want big bore short stoke always , regardless of friction . race engines generally have larger intake and exhaust ports , with appropriate intake and exhaust manifolds, and high overlap cams , all of which provide high rpm power , but kill low end torque .

TheLOUDMUSIC- Put it in H!

> GhostZ

TheLOUDMUSIC- Put it in H!

> GhostZ

09/07/2013 at 13:36 |

|

What I mean by streetable, is it will idle at 2000rpm. And will get single digit MPGs. The whole advantage over the ford, is that it is a stronger block and has a better B/S ratio.

GhostZ

> pdthedeuce

GhostZ

> pdthedeuce

09/07/2013 at 13:39 |

|

Alright. I knew most of this stuff as a general rule, but what I really would like to know is how rod/stroke ratio, and deck height, come into play. Even if you have a short stroke, if your deck is so tall you need long rods, can that cause damage to the engine with sustained high RPM use?

Also, I didn't know that NASCAR switched to EFI recently. Was there any reason other than tradition to stay carbureted so long?

TheLOUDMUSIC- Put it in H!

> BugEyedBimmer - back in the Saddle Dakota Leather

TheLOUDMUSIC- Put it in H!

> BugEyedBimmer - back in the Saddle Dakota Leather

09/07/2013 at 13:39 |

|

Well yeah, but I'm talking old school 'Murican V8s,

GhostZ

> TheLOUDMUSIC- Put it in H!

GhostZ

> TheLOUDMUSIC- Put it in H!

09/07/2013 at 13:43 |

|

The B/S ratio is the same as a Ford 302 (4" bore, 3" stroke), and worse than a 289 (4" bore, 2.87" stroke)

I'll have to look into whether the block was stronger or not. It also looks like the Z/28 race 302s had a lot of special parts not normally found in a 327, which may explain their durability, so converting a 327 to a 302 probably wouldn't be near as good as a "production" 302 from the 60s. But again, I need to do more research on the blocks in particular.

Also, 2000rpm idle and single-digit mpg is fine. We're still in the theoretical space. I imagine a clever EFI system or a multi-stage carb (that opens more barrels at a higher RPM) would take away some MPG woes, considering that most of the parts are going to be pretty light, and if its put into a light car, the only MPG-killer is the single cam for that high RPM usage.

Frank Grimes

> GhostZ

Frank Grimes

> GhostZ

09/07/2013 at 13:47 |

|

I didn't really read what you road and Immma let you finish but,

802 CUBIC INCHES!

Peak 1400 HP at 7100 RPM

Pump Gas

pdthedeuce

> GhostZ

pdthedeuce

> GhostZ

09/07/2013 at 13:49 |

|

Nascar used carbs because they fear change . they were scared teams would "hack" the efi , possibly for good reason . there is actually a lot of discussion about rod ratios , but it seems to be common belief that a long rod is preferable if possible . also a long rod uses a short piston . they material used for the rods determines piston to deck clearance , because steel rods , while heavier than aluminum , stretch less , requiring less clearance .

GhostZ

> Frank Grimes

GhostZ

> Frank Grimes

09/07/2013 at 14:03 |

|

Haha, damn. That is some engine porn right there. Did a google search to learn more, and quickly found that 5" bore spacing is pretty much impossible to find outside of a custom block like that. I'm still wondering how the hell they got a 5.7 inch stroke up to 7100 rpm. That's a mean piston speed of like, 6750 ft/min according to a few calculations.

If I was crazy for absolute power, (within reason and cost) I'd go for a 413 RB block with a 4.45" bore (leaving a .35" cylinder wall) and a custom 3.25" crank to make a 404 with a sexy 1.37 bore/stroke ratio. That's better than a 302, with 30% more cubes. I don't think you can get a wider bore out of a production MOPAR, Ford, or Chevy block.

Or, in other words, mean piston speed reaches 4000 ft/min (which is I think considered pretty safe even for an old motor) at 7500 rpm, and with 404 ci it's probably looking at 500-600HP reliably at that speed.

The WB

> GhostZ

The WB

> GhostZ

09/07/2013 at 14:03 |

|

Woo, this is a tall order for an oppo post. I could write for hours. I'll try to answer what I know in as nutshell a form as possible. To answer the question "what is best," you have to first ask what you're trying to accomplish.

To start with your first part, I'm going to reference a blog post I made a while ago on the rotating assembly. OMG Engines! - Rotation, Rotation, Rotation. It will explain a bit about rod/stroke and impact on powerband/engine purpose.

Increasing the bore of an engine increases the overall torque generated provided you can flow enough air to fill the additional displacement. If combustion pressure is constant but bore increases, torque increases by the ratio of the piston areas. At the same time, like you mention, mass increases as you beef up pistons, requiring stronger rods to take higher RPM, and a stronger crank to take the mass of the reciprocating parts.

Lighter is always better from a strength point of view. However, depending on what type of engine your building (high RPM, high power, low RPM, high torque, boosted, nitrous, NA) you will want varying components. The higher the RPM, the more stress on the components. These accelerations and decelerations are second order, so the faster you go the faster the forces climb. Light rods, hypereutectic pistons, these are usually used for NA high-RPM builds. If you want to add nitrous especially, or forced induction, you likely want to consider forged pistons. However, forged pistons are heavier, have looser clearances meaning more wear, and will limit your RPM. Again, depends on what you want to do.

In a conventional V8, above 6,000 RPM and rotating stress really starts to add up, dominating the cylinder pressure (especially since filling 8 large cylinders above 6,000 RPM takes a lot of breathing capacity from the heads.

Cross plane resonance tuning is rarely even done. For the exhaust side, it requires a "bundle of snakes" configuration impossible on most cars. On the intake side, individual runners can be tuned, but you run into cylinders drawing from the same local volume in the plenum. A small plenum (dual-plane especially, conventional single plane also) is responsive at more throttle positions. A large plenum (I.E. tunnel ram) will give you better breathing at the top end, but only by sacrificing flow momentum at low speed, meaning you won't have much of a bottom end. If you're planning for 7000+ RPM, you will not care about low end.

At 7,000RPM, you will not be running a hydraulic cam. Flat tappet mechanical lifters are required due to pump up and subsequent valve float. Valvetrain mass will have to be minimized, undercut valves, beehive springs, titanium keepers, low mass rocker arms, the valvetrain will be the first limit you run into when you try to run higher RPM.

Valve lash is the overall clearance, or lash, in the system from camshaft lobe to valve stem tip. Lash is automatically taken up in a hydraulic system due to the pump-up nature of hydraulic lifters (tappets.) Mechanical tappets do not have this action, and so there is some small amount of space, or lash, left to accomodate thermal expansion of components. Lash also impacts effective duration of your camshaft. A looser lash reduces duration by requiring the lobe to lift some amount before the lash is taken up and the valve begins to open. Old school hot rodders know more about this than anyone. Solid flat tappets are better from a valve float perspective because they have less mass than rollers, but rollers are more tolerant of high seat pressures required to control the valves with a high-lift cam.

At high RPM, carburetors and fuel injection, at WOT, tuned properly, function identically. The difference is, carburetors need to be jetted depending on changes in local air pressure, temperature, humidity, altitude, and the like. EFI systems do this automatically.

At part throttle, port injection offers better driveability when running a performance motor because the fuel induction point is closer to the valve, leaving less room for fuel to fall out of suspension and wet the walls of the intake tract, especially at low engine speeds when reversion takes place with high overlap cams. This, along with the ability to time fuel injector opening events, leads to better fuel economy due to improved atomization. At WOT, EFI is a constant fog of fuel, just like a carburetor. However, a carbuerator always requires a small amount of restriciton for the venturi effect to take place, so EFI would theoretically edge it out by some very small margin.

2 bolt blocks can be drilled for 4-bolt caps, but the practice is a bad idea. The webbing in 2-bolt blocks is thinner than 4-bolts, and in all likelihood the process of drilling the webbing will reduce the strength of the block overall. You may cure the cap walk, but you'll rip the webbing out.

Which saps more power - displacement or RPM? There's no replacement for displacement. When they build diesel engines for ships, they turn at 200-500 RPM. More RPM means more friction, more flow losses, and a more highly strung engine. That said, there's something primal about a 9,000 RPM smallblock V8.

Circle track longevity is dependent on oiling and bearing speed. Oil coolers, light components, and critically, main journal size. You would think that a larger main journal would be stronger, but in the case of RPM, this is not true. A smaller main bearing spins at a lower surface speed at a given RPM because of the decrease in circumference of the bearing. This is why the "Clevor" engine (Windsor block, Cleveland heads) is big in circle track racing with the Ford guys. You get the Cleveland canted valve high-flow heads with large ports, but you also get the smaller main journals of the Windsor.

RPM forces and cylinder pressure forces stack. More RPM means you're using more of your available strength to keep it together. Failures here are usually tensile failures of the rod bolts. More cylinder pressure also adds to stress, typically in compression, leading to piston skirt breakage, rod bending, and most often, journal bearing destruction due to metal contact. (Insufficient oiling)

Tall deck height typically impacts a few things - compression ratio, quench, and squish. If you increase your deck height without increasing piston pin height, you decrease compression ratio, you decrease squish, and make your quench volume increase - all things that reduce power. This is why adding a thicker head gasket to cure detonation is not a very good idea - you might decrease the compression ratio, but by decreasing your quench area and reducing squish (squishing gas near the outside of the bore towards the middle) you actually increase the likelihood of detonation.

I hope that sums up some of your questions. For the question about specific engines, there is no match for the Ford 289 when it comes to RPM. The Chevy 327 is also very good. The smaller the displacement, the easier it is to take the strain of high RPM (think about motorcycle engines) because the stress-RPM function is squared, but torque is fairly linear.

All pre-1983 ford 302 blocks are identical. They moved to a weaker casting in the late 80's and 90's and also switched them over to roller cams. Any rotating assembly from a 289 or 302 will fit in any other 302 or 289 block pre-1983. You should keep in mind the 80's engines switched to 50oz imbalance vs 28, so be sure you get the right damper and flexplate/flywheel. Most of my knowledge is Ford based, so maybe a Chevy guy can chime in.

That's all I know in a nutshell, hope it helps. My blog also has some more maybe relevant topics if you want to check it out.

GhostZ

> pdthedeuce

GhostZ

> pdthedeuce

09/07/2013 at 14:08 |

|

The way I've always thought about it is for the same length, a longer rod/shorter pistons weighs less, meaning you have less G-forces, but because it's a longer, skinnier, thinner piece (than a big block piston) they tend to break more if they increase in length without increasing in girth/material strength, whereas a longer piston causes higher g-forces, but can take the added force by merit of weighing more.

Then there's also the issue of the angle of the con rod to the piston, which I'm really not sure about until I figure out how to calculate peak piston G forces anyway.

So the ideal way would be a short deck, short piston, long rod, short stroke? Aka: the Ford 289. The bore is just relatively small on the 289 (compared ot the 460 and mopar engines).

Or would long deck, short piston, really long rod, short stroke be a better combo? Like some kind of de-stroked 460 or 440?

pdthedeuce

> GhostZ

pdthedeuce

> GhostZ

09/07/2013 at 14:17 |

|

from what I've read , for a engine like you describe , a tall deck , long rod , big bore , short stroke engine is what you want . you are more likely to break a piston than a rod . at high rpm , you might pull the pin out of the bottom of the piston . as for angularity , less is better , to lessen friction from pushing the piston into the cylinder wall , so the long rod helps there .

GhostZ

> The WB

GhostZ

> The WB

09/07/2013 at 14:24 |

|

Brilliant post.

As it stands, it looks like I'm going to look at as an N/A long-term build:

Ford 289 Hi-Po or Mexican block 302 (they were about the same strength-wise, right?) with slight overbore (.03", 289 crank, to a 306)

Godly

connecting rods, forged pistons, stronger main bolts/studs and bearings

AFR185 heads (they seem to have the best flow for the $ without getting into race heads) some stronger valve springs, a custom-grind solid roller cam.

Some pro-comp exhaust manifold, ITBs, stacks, and an EFI conversion.

I have one more question: how does a turbo and RPM come together? If you put a turbocharger on an engine, I assume the size of the turbo determines the RPM it would peak at, causing low-end loss (since it requires lots of exhaust to spin a heavier turbine) but it peaks at a certain RPM, before it can't flow any more, right? And bigger diameter turbos have a So on a cam set for high RPM, if you put a tiny turbo on it, will it "flatten" out the shape of the curve? Likewise, a large diameter turbo would make the curve more peaked? Or does it not work like that?

I've had 'Maximum Boost' by Corky Bell downloaded on my PC for about a year now, and I just haven't gotten around to reading it.

My dream engine before this post was an E85 high-RPM turbo 302. Something like a 9000 rpm capable 302 brought down to about 7000 and with about 10psi on 9:1 compression (this is possible with E85 I believe, with a water-to-air intercooler). Crack pipe dream, sure, but damn that sounds wonderful.

EDIT: Also, part of me wants to say 'fuck it' and put an ebay turbo on a junkyard stroker 5.0 with decent heads just to pull a dirt-cheap 350-400HP. I could probably blow 4-5 of those motors before they'd cost more than what I'm describing...

Frank Grimes

> GhostZ

Frank Grimes

> GhostZ

09/07/2013 at 14:26 |

|

I enjoy your writings. I dont know much about motors and you obviously know ore about the maths and engineering type stuff. I usually just lust after a motor that is light and somewhat cheap to build that can make some decent street power.

I would like to know what you end up building and the reasons etc.

Frank Grimes

> GhostZ

Frank Grimes

> GhostZ

09/07/2013 at 14:31 |

|

Basically I don't know a lot about this stuff. I just like this thread and want to contribute in any way I can even if that means posting "Hey look at this!"

Along that theme here is an Indy V8 Ford. I love how high this thing could rev and learning what they did to tame it down and move the power into streetable rpm range.

http://www.carcraft.com/techarticles/c…

GhostZ

> Frank Grimes

GhostZ

> Frank Grimes

09/07/2013 at 14:34 |

|

I'm looking at engine swaps for a project Z to make a track car. I've been pretty dead-set on a 289 or 302 for now.

My ultimate ambitions are something like a twin turbo dual intercooler high-RPM E85 302 to put down around 600 reliable WHP at 7000 rpm with 10psi, dropped into a S30Z chassis that has been stripped, seam/stitch welded, reinforced, connected to a TKO 600, short-throw pistol-grip shifter, R230 w/custom halfshafts, and some... *ahem* really tricky aerodynamic systems that I'd rather not reveal here, lest someone with more money go and patent it for me before I can.

It should end up as a 10-second drag car that is respectable around a track and still looks good, for less than a New Camry. I'm thinking $5000 in the car, $2000 in the body, $12000 in the engine (with a pick-a-part block and 10,000 in mods) $5000 in the transmission, and the rest for a few bits and bobs here and there.

If I have a choice, the only time I would be inside a FWD 4-door if its the hearse I'm buried with. And that's assuming I forget to specify against it in my will.

The WB

> GhostZ

The WB

> GhostZ

09/07/2013 at 14:37 |

|

The biggest thing to watch for is core shift on the blocks. You're not going very big on your overbore, so that won't likely be a problem, but if you're going for ultimate strength, have the block sonic checked. Even a regular 302 block will be as strong as the Mexican blocks if you confirm the cylinders are in good shape. That said, if you make your bottom end bulletproof, the weak point will be the block. Even the strongest OE castings will part between the main web and the cam bearing bosses if you spend much time near 500HP. That number will go down if you are doing so at a very high RPM. If you have a 500HP motor with an OE block, it's not a question of if, but when it will split down the middle.

Another thing you can do is blueprint and deburr the block. By smoothing out all the casting flash and ridges, you remove stress risers and can improve strength (as long as you don't remove a lot of material)

If you go with the 289 crank, you'd need the 289 rods unless you get custom pistons with the appropriate wrist pin height to keep them from sitting way low.

AFR 185s should be more than enough, but avoid the Pro-Comp. Get a good set of Hooker Super-Comp's. The cam grinder will be able to suggest a valvetrain that will take the grind.

ITB's are cool, but they are much harder to tune due to individual throttle opening. If you go that route then props, it's not the easy way to be sure.

As for turbos, remember they only care about air flow. Whether that airflow is from high displacement or high RPM they don't care. You estimate the airflow you need to make the power you want, figure out the pressure ratio you want to get it, and try to put it in the most efficient part of the compressor map.

I'm by no means a boost guru, but you have to make sure your cam cooperates with your turbo. If you have a high overlap cam, you'll breathe more at the top end, which means you can go with a lower pressure ratio turbo (and likely smaller one) to make the power you require. The cam grinder will be able to point you in the direction of a turbo-friendly grind.

A tiny turbo on a huge cam sounds like a recipe for poor performance though, the turbo may become the bottleneck especially if you flow so much through it that it overspeeds and craters. It's not just the diameter of the turbo, it's also the vane configuration that influences the compressor map. The map is critical for sizing the turbo for your performance goals.

GhostZ

> Frank Grimes

GhostZ

> Frank Grimes

09/07/2013 at 14:38 |

|

Woah woah woah. Stop the presses. That thing is perfect.

I wonder if those DOHC kits are still available for a 260/289...! That would be insane! If they were based on production blocks, you could easily build one with a wider 4" bore (no race restrictions) for a DOHC 289... sexy.

I'm going to have to do more research into this. Thanks!

GhostZ

> BugEyedBimmer - back in the Saddle Dakota Leather

GhostZ

> BugEyedBimmer - back in the Saddle Dakota Leather

09/07/2013 at 14:42 |

|

BMW and Audi engines do not lend themselves to swaps very well. But the 4.2 FSI is, in my opinion, pretty close to the most perfect V8 ever built, right behind the Cosworth DFV.

Frank Grimes

> GhostZ

Frank Grimes

> GhostZ

09/07/2013 at 14:44 |

|

What about an aluminum block GM 5.3?

Why this engine?

Well basically I am no expert but my thinking is

Modern block heads crank etc. benefits that come with that over an old 302.

Cheap.

Lost of aftermarket support. Heads Cams cranks etc.

Aluminum block for lightness and weight balance in the car.

They make great power with little effort. 600hp is quite easy with little boost.

GhostZ

> The WB

GhostZ

> The WB

09/07/2013 at 14:50 |

|

It seems like my choices are either a $500-$1000 pick-a-part 302/289, or a $4-5000 4-bolt main aftermarket race block.

If I'm aiming for 350-400HP now, and 500-600HP later with boost or spray, I should be looking at aftermarket blocks then?

If I wanted to stage the build, could it be worth getting a stock 289, throwing some good heads, rods, a bore, custom pistons and solid cam in now, and then later (when the budget may open up larger) going for a new race block and fitting the internals into it, along with a new intake, exhaust, etc?

I feel like I have a good enough knowledge on the intake (and access to some people who really know fluid dynamics) that ITBs won't be too hard to deal with, but my biggest concern is height. If I put this into an S30Z (which is my plan) A tall plenum may be too high and it will cause a hole to be cut in the hood. I know that a decent intake and carb on a Chevy 350 can stick out the top if you don't mount it low enough. I'd want to keep the hood stock, so I may have to do custom mounts to get the engine low and back enough to clear.

Width? Not a problem at all. You could fit a big-block hemi into that thing width and length-wise, but it's just not tall.

GhostZ

> Frank Grimes

GhostZ

> Frank Grimes

09/07/2013 at 14:56 |

|

The 5.3 has a pretty long stroke (3.622") for its bore size, but if it's significantly cheaper, that is definitely a possibility. I'd get a few more cubic inches over a 302, but the stroke would be a lot longer and I doubt the block would be able to handle a 4" bore. They did make a 4" version, according to wiki, but de-stroking it could be a pain. I don't know Chevy engines though, so this is still new territory.

The thing is, I know a used 302 will have just as good aftermarket (if not better) and be cheaper, it's just a matter of whether or not it can handle the power before the block cracks. Since most of the internals are going to be aftermarket anyway, a modern block is the only advantage with the 5.3, but I don't see that being with taking the hit on high-RPM potential.

The WB

> GhostZ

The WB

> GhostZ

09/07/2013 at 15:08 |

|

350-400 is easily doable and you'll get a good amount of time out of the block. If you're going to spray it, go with forged pistons. Hypers like to explode under the shock of nitrous combustion. You can do boost with hypers, but you have to be absolutely sure you don't detonate. They don't deal with it very well.

You could always upgrade your block when you made your changes, that works just fine.

As far as ITB's, it's not the fluid dynamics, it's the linking of 8 butterflies to be synchronized that's the most difficult part. The linkages can be a pain to adjust. But, if you have a buddy who's ever synched motorcycle carbs, it's just about the same thing.

GhostZ

> The WB

GhostZ

> The WB

09/07/2013 at 15:19 |

|

Now the question is: How to budget for all of this. I've had this engine idea floating around in my head since I was about 18 (2 years ago) and I've done on-and-off research, including using some engine simulator programs (Engine Analyzer Pro 3.7) to spec it out. Basically I want an engine that is about 50% Cosworth DFV, and 5% the cost.

Maybe you could answer this though. Get ready for a doozy...

My father, when he was young, had a 1970 Dodge Challenger, purchased new. He had the 440 thrown out and replaced it with a 413 out of Chrysler Crown Imperial limousine. Hooked up to a Dana 60 rear end and a 4-speed Nickel-cut stock car transmission, he could turn a flat-10 second quarter mile in 1971. The engine dyno'd for 850HP at 8500 rpm, N/A on nitromethane, high compression (I'm guessing about 14:1) and two 4-barrel carbs.

How would one go about making an engine, back then, that could handle the RPMs without blowing apart? He said he had it touch 10,000rpm a few times, but generally shifted around 8500. The engine never broke, though it destroyed spark plugs constantly.

The WB

> GhostZ

The WB

> GhostZ

09/07/2013 at 15:25 |

|

Haha, I can't answer the budgeting question. Sell a kidney maybe?

My dad had a 327 Chevy running on avgas in the mid 70's that spun to 9,000RPM regularly.

Forged crank, forged internals, and a short stroke engine all help that out a lot in his case.

Especially in a limo motor, which is designed to run forever and take all kinds of abuse. I bet the 413 shared a block with the bigger displacement motors, but was destroked and had all forged internals. Short stroke length makes it live a lot longer. The nitromethane is a good way to fry the rings real quick, but if he cut it with gasoline it might have been ok. I do have to say, in hindsight, cars are always a lot faster than they really were. Just like the fish stories. ;)

GhostZ

> The WB

GhostZ

> The WB

09/07/2013 at 15:49 |

|

I'd love to get a jump start on this before I graduate college (and if I wasn't at school, I'd already be done with it) but what I really need is someone who has an aftermarket 302 block that they built to around 350-400HP that they're getting rid of, in favor of a bigger engine, and are willing to part with it for cheap. That way I can start with the good block right off the bat, and get a good 289 crank, a carb tune, and a custom grind cam to throw in there to bring it up in RPM.

What's funny is that with a properly built chassis, putting this thing in an S30Z will actually bring the weight down (to about 2200lbs, maybe 2100 with an aluminum block) and 400HP is killer with that. Considering the fastest car I've ever driven was a 425HP Camaro SS (2010 and 2012 respectively) It would certainly be a handful... The Camaro felt really lacking in power though, as if it could have used another 200HP before it would excite me. 400HP is about the limit the body can handle before it starts getting really shaken up, so if I want to do anything over, I'm going to need serious reinforcement.

The WB

> GhostZ

The WB

> GhostZ

09/07/2013 at 16:00 |

|

That would be nice.

And yeah, the 350HP my 302 makes doesn't sound that impressive, but in a 3,100lb car, it scoots pretty good when compared to the 4000+ lb monstrosities they make these days with 430HP

GhostZ

> The WB

GhostZ

> The WB

09/07/2013 at 16:10 |

|

What are the specs on your 302? Is it in a Fox Body, I presume, or something older?

I also seriously considered buying a beat up Fox Body to drive while in College and work on the engine, then give the heart transplant to the Z when I could afford it, but it wouldn't have been worth the garage/registration/insurance costs for a few years compared to being able to just afford to do the work all at once.

There's also the issue of torque. I'm a fan of "low torque motor, great gear ratios". I don't believe in the "If you don't have low end torque, your car will be slow" myth. I think it's something that was told to people back in the 70s so they could get away with 4500 rpm peak power levels on cheap parts. I truly believe that a light car with 300-400 HP and a good driver is infinitely better than a heavy car with that extra 100HP. Look at the Challenger 392 (525HP) and the Mustang GT (412 HP, about as fast).

My first car was a 1998 Mustang V6. 150 HP on a good day, but a redline of 5000rpm. The motor was a dog. A reliable dog, but a dog nonetheless. Still, on saturday nights, I learned to make that car dance and corner better than a civic to make up for the lack of power.

The WB

> GhostZ

The WB

> GhostZ

09/07/2013 at 16:33 |

|

It's a 1967 coupe. The 302 is a 1969 block, stock crank, Eagle I-beams, KB 166 hyper pistons, Roush 200 heads, Vic Jr. Single plane knockoff with EFI, and Hooker Super Comps.

GhostZ

> The WB

GhostZ

> The WB

09/07/2013 at 16:39 |

|

That sounds beautiful. I've always loved the First-gen Mustangs (they were my first car-crush and the reason I used to own a 1998 Mustang) and right now a decent I6 one isn't too expensive. If my love for the less-expensive-right-now Z wasn't so strong (as well as my want for IRS) I'd have considered one of those instead.

How did the EFI conversion go? I'd like to go EFI with this build if possible, and maybe run E85 (with the appropriate lines, injectors, fuel tank, and pump) if I want to go with boost later on, to keep temperatures/knock possibilities down.

The WB

> GhostZ

The WB

> GhostZ

09/07/2013 at 16:41 |

|

It was straightforward but I've done several systems from scratch when I was in FSAE. I upgraded a lot of things when I did it, fuel cell, alternator, electric cooling fan, etc.

The only thing keeping me from being able to run E85 is the fuel injectors, I've got a fuel cell and plated lines, maybe one day I'll upgrade to viton injectors and make it flex fuel.

matthewklein220

> GhostZ

matthewklein220

> GhostZ

09/07/2013 at 18:40 |

|

It wasn't a kit. They were prupose-built engines for open-wheeled cars in the 60's. And what is this insanely-high-revving V8 (in large-displacement V8 terms) going into?

GhostZ

> matthewklein220

GhostZ

> matthewklein220

09/07/2013 at 20:35 |

|

Ah, okay. I did some research and it doens't look like any reasonable-cost and non-custom 302 DOHC conversion was available. Which I completely understand.

I'm thinking of dropping the 289/302 into a S30Z chassis. Either a early '71 one I have access to now, or another one (preferably 75-77 with a 5-speed) in a year's time or so when I'm closer to graduation. It serves more than an aesthetic purpose: that car is pretty damn light and too much torque could kill its ability to handle the power. The small block ford is pretty much perfect, since A: it matches up with the stock 5-speed (BW T5) B: They make engine mounting kits for it, and C: it weighs about 100lbs less than the stock L6 motor.

If the money is there, I'd like to strip the whole chassis down, carefully weld its components and add some structural bracing and a roll cage, piece together a custom interior, drop the motor, a TKO600 transmission and a number of techno-telemetry gadgets into it for a 20% street 80% track car. 400HP @7000rpm and about 300 ft/lbs at @ 5000 rpm is plenty for 2200-2400lbs, and if I go into boost later on in the car's life (depending on how the chassis is holding up) I'd like to touch 9-second quarter mile times, which is definitely possible with 600HP.

matthewklein220

> GhostZ

matthewklein220

> GhostZ

09/07/2013 at 20:42 |

|

Sounds like your building yourself a rocket! A 302 would probably be more than the little Datsun would ever need. But depending on where you live, you might want to get the earlier model. Since, like my home state, pre-'75 cars are smog exempt.

GhostZ

> matthewklein220

GhostZ

> matthewklein220

09/07/2013 at 20:49 |

|

Smog exemption starts at 25 years or older where I am, so I'm good there.

I'd really prefer a later model so I could avoid a differential and transmission change when starting out. It would let me run the car with a low-HP 302 for a little bit before redoing the chassis, and let me do bolt-ons with instant results (instead of having to test and build the whole engine outside of the car) but it all depends on whether or not I can find a good chassis with low rust. If I have to go with an earlier body (which I will receive more flak for 'ruining') I won't be able to put the engine in without doing the transmission, differential, drivetrain and rear axle at the same time.

Really, the only reason I'd go with a V8 is because RB motors are absurdly expensive, and there isn't much potential in the L engine. An RB25 will run you $10,000 and net you 300-400HP with rare and unreliable parts, and RB26 will run you $20,000 and net you 400-500HP with more reliability, and a 400HP L engine will run you $ 30,000 at race-only compression or very unreliable turbo setups.

matthewklein220

> GhostZ

matthewklein220

> GhostZ

09/08/2013 at 02:28 |

|

I am jealous of your smog rules. And a Ford 302 would be a lot cheaper, that's true. In California, some of the drift guys drop them in their 240Z's/S14's for the same reason you don't want an RB.

GhostZ

> matthewklein220

GhostZ

> matthewklein220

09/08/2013 at 06:16 |

|

I've seen a lot of chevy small block swaps, but I'd prefer to go with the 302 because while the SBC is about the same weight, the 302 is a little lighter, and the SBC doesn't have as high of revving nature. Consider that the 302/289's journal

The real problem will be finding a good 289 crank. I'll probably have to scour the junkyards for old 60s Fords, because no one makes a decent aftermarket crank. Everyone wants to go up in cubic inches, not down. I say, more revs, bore, and boost. Leave the strokers for the tractors!

Sadly, the only way to get huge HP out of a L engine is to go with a very specific set of parts, most of which are no longer manufactured. You'd have to go with a Fuel Injected L28, with a Maxima LD28 crank and a small overbore resulting in 3.1liters. Then, you need an OS Giken DOHC Crossflow head conversion. That, in combination with good tuning or excellent carbs, will get you a 400HP 3.1 L28 for 30,000$. Without the Crossflow head, you need boost to break over 300 HP. You need high-flow L28 heads and L28 turbo dished pistons. The highest you can feasibly get is about 500HP before reliability really becomes an issue. But if you have ever watched Wangan Midnight or researched the Mid Night club it was baed on, 600HP on an L block is possible, just prohibitively expensive nowadays.

For the same cost, you can make a custom block 302 hold 25 PSI and make 1000 HP... or buy a whole new car for the cost of the engine alone.

matthewklein220

> GhostZ

matthewklein220

> GhostZ

09/08/2013 at 17:22 |

|

There may not be any 289 cranks out there, but there are plenty of guys going from 289 t0 302, so there should be a pretty big market for 302 cranks. Also, stroke=torque. and torque is your friend.

GhostZ

> matthewklein220

GhostZ

> matthewklein220

09/08/2013 at 18:05 |

|

Stroke doesn't equal torque, and a long stroke motor has no advantage (really!) over a small stroke one. They have the same torque, increasing the stroke just narrows it at a lower RPM.

Stroke brings down the peak flow RPMs. Low peak flow RPMs = "more torque" because you are making less top-end power. Peak piston velocity goes down the same amount, so if you double the stroke of an engine, the crank/piston/rod will blow (whatever is weakest) at half of the RPM (generally) Ignoring the valvetrain, that means that any additional cubic inches you gain by stroking, you lose RPM in the same proportion. Dropping RPM for Cubic inches means you don't gain any power, you're just narrowing the range in which your engine can produce good torque.

Low-stroke motors flatten out the torque band and drop it, spreading it over a much wider RPM. That's why they're great for lightweight cars. (think: F1) The reason stroke is so enjoyed by builders is because most stock valvetrains are designed for low RPM street use, and most stock engine components will wear out at high RPMs. Shorter stroke also lets you use longer rods, and the rod/stroke ratio determines the angle the piston is being pushed up against the wall. This can really save your engine some wear and tear by reducing this.

HP is your friend. Torque just decides how it is applied, and in a light car, torque is not your friend. If you want to keep traction in a 2000lb car, go for something that will accelerate like mad up to high RPMs.

A 408 stroker that's making 500HP @ 4500rpm is significantly worse (for a lightweight car) and going to be a lot more unreliable (torque stresses components more) than a properly-built 500HP @ 7500rpm motor. The problem is, a 408 stroker doesn't cost much to make, and a high-revving motor requires a lot of new parts.

The trade off is that if your car is facing lots of resistance (for example, weighs a lot, or is traveling at 150+ speeds that cause lots of air resistance) then you need more peak torque to continue accelleration, otherwise forces get upside down and you top out. Notice how an F1 car seems to hit a brick wall and accellerates much slower after 180 mph or so. One of the reasons a Ford GT is so damn good at top speed runs is its insanely long stroke compared to its bore.

After 400HP though, it doesn't matter what stroke you have, you're going to have to replace the heads, cam, rods, and pistons (and maybe go to a new block) anyway to gain more. If your car needs more traction, a short-stroke motor is great.

So, in other words, putting a 289 crank (pick a part) lets me put 289 rods (about .1" longer) and stock 302 pistons. With new heads and cam, I'm making just as much power than I would be if I had put the heads and a different cam on the 302. I'm making less torque, but in a lightweight car, that doesn't impede me, and actually lets me run the stock transmission.

When I want to turbo it later, that short stroke is extremely advantageous, because it lets me keep a low compression ratio (good for preventing knock on a turbo) without using shorter (which are worse for high RPM) rods. Since I'm increasing both the boost I can run, and the RPM I can run it at, the gain is exponential compared to just increasing displacement.

matthewklein220

> GhostZ

matthewklein220

> GhostZ

09/08/2013 at 18:31 |

|

Very true, I don't have a high revving engine, thus I want lots of low-RPM torque. And I see your reason for wanting a 289 over a 302, but as you said, finding an aftermarket 289 crank is very difficult. And above 5,500 rpms, I wouldn't trust the stock crank and rods very much.

GhostZ

> matthewklein220

GhostZ

> matthewklein220

09/08/2013 at 18:47 |

|

I actually think that a stock 289 crank would do fine until I pushed it over 400HP, and if I can afford that, I think I'll probably just have a crank made for me at that point. Remember, RPM is relative to the length of the stroke. The stock 289 is good for up to about 7500 and the 302 is good for about 6500, depending on how much HP is being produced by the combustion (stronger explosion will break easier, obviously), and both can take 400HP (even a stock crank in a 1990s 302 can do 400HP, just not for a long time, and I know they are weaker). But the stock heads don't make power past 5500.

Long before the crank fails at high RPMs, It's the block mains that could go, and the pistons. That's why the 302 Mexico block is the way to go. I'd just get a 289 and be done with it if it wasn't for the fact that equivalent high-strength (larger) mains for a Mexico 302 is a 289 Hi-Po (mustang) engine. With today's restoration culture, junkyard Hi-Po 289s are much harder to come by.

Think about it this way: A 351 windsor spins a lot slower (5500 rpm even for modified motors) but if it had the mains the ame size of the 302, they'd snap because of the much heavier (longer rods, bigger stroke crank, taller pistons) reciprocating assembly. Same goes for a Ford 460.

So yeah, a stock 289 block probably wouldn't be trustworthy over 5500 rpms. But a Mexico 302 (or a Hi-Po block) with good pistons, aftermarket bolts, 289 crank, and longer rods, could probably do 6500-7000 relatively fine. I won't make any power there, but it will spin without blowing.

matthewklein220

> GhostZ

matthewklein220

> GhostZ

09/08/2013 at 18:55 |

|

Yeah, if you want to get 400HP above 5,500 rpms, you'll need aftermarket heads and possibly a cam. There are companies that make heads that flow enough air for you to probably still be making power at 7,000.

GhostZ

> matthewklein220

GhostZ

> matthewklein220

09/08/2013 at 18:57 |

|

I plan to do AFR 205 (or Dart if the money is there) heads, with stiffer valve springs.

If I was crazy? I'd get the 32V heads that Dominion/ARAO makes. At about $6000 a piece, they're insane, but they work on a single cam and provide about 20% better flow than anything else on the market.

matthewklein220

> GhostZ

matthewklein220

> GhostZ

09/08/2013 at 18:58 |

|

I've always wondered if it was possible to have a 4-valve OHV. How does it work?

GhostZ

> matthewklein220

GhostZ

> matthewklein220

09/09/2013 at 01:00 |

|

They take a single camshaft and run it to rockers that operate dual valves.

So you end up with two small, canted valves, working off the same rocker and camshaft profile. This gives you the advantages of 4v (larger valve area, lighter parts, better springs for the weight, better valve angle) with the simplicity of a pushrod system. It's a single pushrod to a two-part rocker (which may have different rocker ratios for each side if you wanted) to two valves (which could be different sizes).

So for the same size springs and weight, you get a much larger valve area, and a lot better flow since the combined valve lift / area to flow through is larger. To put it in perspective, most aftermarket 2000-3000$ heads (Dart, AFR, Ford Racing, etc.) have 2" intake and 1.6" exhaust valves. The ARAO heads have 2 intake valves at 1.65 and 1.4" exhaust valves.

Total valve area for standard 2/1.6" is 3.14 in.sq. intake, and 2 in.sq. exhaust. (one large circle each)

Total valve area for the 4v heads is 4.27 in.sq. intake, and 3 in.sq. exhaust. (two small circles added together)

So even the best 2v heads just can't have the same overall valve area without using massive heavy 2.4 diameter intake valves and 1.95 diameter exhaust.

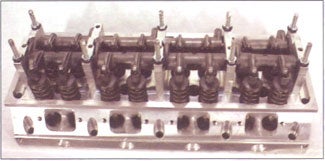

Here's a picture of the ARAO heads:

Oddly enough, flow increase and HP gains are both about the same as the valve area increase, about 30%. Supposedly even a well-built 302 with a good head that makes 300HP can jump to 400+ with just adding this new 4V head on, and rev to a much higher RPM.

Combine that with a 10:1 compression ratio and high revs... it's no wonder that the new 5.0 4V Coyote makes 412 HP stock. And it even has 2 camshafts per cylinder! This one is using the same profile for both valves!

Another similar head is the OS Giken head for the Nissan L engine, which added 4v, hemi, and crossflow characteristics to a non-crossflow 2v head. Power gains were from 150HP to 230HP with those heads, even more of a gain that goes to show how much benefit crossflow heads are to non-crossflow ones. Here's a pic:

I guarantee you, if my current business plans for coming out of college pan out and I have enough money to play with, I will be getting a pair of 32v heads for the 289. The idea fascinates me, and 6000$ is not totally unreasonable for a 30% gain in flow over good ported heads.

matthewklein220

> GhostZ

matthewklein220

> GhostZ

09/09/2013 at 03:07 |

|

To me it always seemed impossible to get two rockers and two pushrods to move four valves. Whenever I tried to picture it, something would always end up in the way of something else. The fact it actually exists is too much for me to handle!

GhostZ

> matthewklein220

GhostZ

> matthewklein220

09/09/2013 at 08:45 |

|

I think its one beefy pushrod (since there's only one cam lobe) and one large rocker, moving two smaller valves.

matthewklein220

> GhostZ

matthewklein220

> GhostZ

09/09/2013 at 16:46 |

|

You need to get those heads just because of how amazing that is.

GhostZ

> matthewklein220

GhostZ

> matthewklein220

09/09/2013 at 16:50 |

|

The problem is in the business's size. From what I've read, it takes about 6 months to get them, and a few years back someone was waiting 2 years and forum spam'd about being 'ripped off'. The company used to hand-make the heads out of billet aluminum. Now they are cast.

That being said, if in the last few years they've gotten to the point where I can order them and have them shipped within a few weeks, then they are suddenly really appealing. But $3000 more (the price of a small turbo system) and waiting 6 months might not be a good idea, especially since if any part goes bad, I have to wait just as long for them to send me replacements or service on them.

matthewklein220

> GhostZ

matthewklein220

> GhostZ

09/09/2013 at 20:32 |

|

Jeez, so now it's a debate between quality and practicality? Get the amazing heads that might take too long, or get slightly worse heads that are available now?

GhostZ

> matthewklein220

GhostZ

> matthewklein220

09/09/2013 at 21:18 |

|

Basically. I'm less concerned with how long they take to arrive, and more concerned with having to deal with the provider if something goes wrong or they are delayed. They probably do not get orders for these heads frequently. 6000$ can buy you some extremely good race quality ported 2v heads with excellent valves and springs, so the gains have to really be worth the money and time for me to justify it.

matthewklein220

> GhostZ

matthewklein220

> GhostZ

09/10/2013 at 00:45 |

|

And I take it those heads aren't available through Summit...

7liter12598723

> pdthedeuce

7liter12598723

> pdthedeuce

09/10/2013 at 17:37 |

|

The principle driver for EFI in NASCAR isn't power or efficiency, but that it allows NASCAR to mandate a 9,000 RPM fuel cutoff line. Several teams were pushing the old carbed motors past 9500 RPM on some tracks, and NASCAR wanted that to stop.

7liter12598723

> GhostZ

7liter12598723

> GhostZ

09/10/2013 at 17:45 |

|

With many pushrod V8s, the actual limiting factor in RPM is not your bottom end. a 400 ci (4in bore, 4 inch stroke) SBC pattern V8 can be pushed past 8,000 RPM, if your valve train can take it (cam, lifters, pushrods, rockers, valves, valve springs), if your water pump won't overspeed (blowing the frost plugs out of the block), and if the heads flow good enough to support your displacement at that RPM (because you'll never be able to cam it enough to make high end power if you can't get enough flow).

So, if you are building a Small Block Chevrolet pattern motor, and you want to spin the bejeesus out of it, your first step is to pick the best flowing heads you can afford, your second step is to pick a block that has the correct bore for the heads you chose, your third step is to figure out what's the most displacement your heads and your cam can support at your target RPM, your fourth step is to choose the lightest, strongest crank that gives you the correct stroke for that displacement, and your last step is to break your budget buying high test valvetrain components.

GhostZ

> 7liter12598723

GhostZ

> 7liter12598723

09/10/2013 at 17:59 |

|

I've gotten a lot of great feedback since this post. I wanted to separate the difference between not making power at a certain RPM (where pumping losses cause extreme stress) and blowing up at a high RPM (where it is running normally and making power, but some component snaps). It's definitely true that heads won't flow at higher RPMs, but they aren't usually going to explode. Valves and cams will float, but I knew that going into this, so I'm sticking with solid cams and not hydraulic.

If a solid roller cam is a given with solid lifters, the valvetrain can easily handle RPMs before the crank or rods go it seems.

That being said, a longer stroke does increase the force on the crank, pistons, and rods, but having a low-stroke and a long rod can reduce the force too. So on a stock crank, increasing stroke and RPM could be a quick recipe for disaster.

It looks like my best bet is to go with a Ford Mexican block 302 from an early-70s car, with a 289 crank and rod on the stock 302 pistons. The assembly is stock and the Mexican block castings have stronger mains than the regular windsor engine, and are good for much higher RPMs. The longer 289 rods will also help reduce the angle that the piston is pressed up against the wall, reducing friction and improving engine life at higher RPMs. There are better engines out there, but nothing that can be found nearly as cheaply. Then a pair of high-flowing heads (Dart, or AFR with springs and valves) and a high duration cam should give me a reliable 7000-8000rpm V8 and tie me over.

Long term goals would be switching those parts over to a new block that can handle light turbocharging.

MrBillG59

> GhostZ

MrBillG59

> GhostZ

09/14/2013 at 23:06 |

|

The first question is why the heck do you think you need your engine to turn 8,500-9,000rpm?

Power gets made by moving air. You can move air in either of two ways, high RPM's or large displacement. High RPM engines are usually built because the racing class limits the displacement. This is why the current Formula 1 engines, 3.4l (146ci) have to turn 18,000rpm to produce about 740hp. In NHRA Pro-Stock classes, the engines are limited to 500ci (8.2l) and produce about 1,250hp @10,500rpm. In "mountain-motor" pro-stock racing the engines are 825ci (13.5l) and produce 1,900hp but at only 8,000rpm.

The second way power gets made is by compression. Street engines generally run 8.5:1 - 10.5:1 compression rations, but racing engines can run 12:1, 13:1 or even 14:1. The problem is as the compression ratio goes higher pre-ignitionn becomes a problem and compression ratios beyond 10.5:1 are usually impractical using gasoline that is readily available (pump gas, not racing fuel). Supercharging, turbocharging and nitrous-oxide injection are other ways to increase the effective compression ratio of an engine.

Are you building a street engine or a racing engine. Many of your decisions may already be made for you if you have to meet the requirements of a racing class.

You should also read the information that you can find at web-sites like:

http://hotrodenginetech.com/inside-warren-…

http://www.enginebuildermag.com/Article/89943/…

I'd also recommend that you start reading back issues of "Hot Rod" magazine. Every month they discuss how to make engine building decisions depending on your needs.

GhostZ

> MrBillG59

GhostZ

> MrBillG59

09/14/2013 at 23:24 |

|

You must have missed the first part of this series, but I'll give you the brief:

Let's say you have a 2400lb car.

Which would you rather have? 400HP and 450ft/lbs? Or 400HP and 300ft/lbs? Give me 300ft/lbs so the body doesn't twist up and the tires aren't shredding.

The goal is to build a good power V8 for a street/track Datsun 240z that A) won't disrupt the weight distribution too much and B) won't shred tires because of how light the car is. To do that you need to use a higher-RPM engine that produces the same torque, but spread out over a larger RPM range (thus dropping the peak) and getting proportional power at higher RPMs. If I was building this for a truck, I'd be concerned about having enough torque to overcome the resistance of the truck's weight at speed, but at this point, torque is actually the enemy of the build.

I know pretty much everything you posted, and there's a few facts you've got wrong (compression ratio doesn't "create" power, it improves volumetric efficiency, which is the real way to improve power, but is only one factor. Turbos/Superchargers effectively increase the volumetric efficiency ). If you do the calculations, you'll notice that increasing the boost (atmospheric pressure is 1 bar, +14.7psi of boost is 2x, etc.) increasing the RPM, or increasing the displacement, by the same factor, will each increase the power by that exact same factor provided other characteristics at that RPM stay that same. Obviously this isn't true for normal engines because the heads, intake, exhaust, etc. are all tuned for a particular RPM to give the right VE's for that combustion cycle. Some cars optimize for a single point, others spread it out to get more even powerbands.

I'd love to build a high-compression 500ci engine with a blower and nitrous. But not only will it murder the car's handling and balance, but it will also require a lot more work to fit inside, even if it can.

And the final point, of course, is "because I can". Not only would a high-RPM V8 be significantly better than a low-rpm V8 at the same power for this application, but it would be fun as hell to drive.

GhostZ

> MrBillG59

GhostZ

> MrBillG59

09/14/2013 at 23:28 |

|

Haha, I thought you responded to my second thread about this. Sorry about that. This is the old first thread, so sorry about the first post. I just made a new thread where I'm comparing a Ford 289 Vs a Chevy 302, where those engine mounting ideas come into consideration. Thought your comment was for the second thread.

The rest of my post still stand though.

MontegoMan562 is a Capri RS Owner

> GhostZ

MontegoMan562 is a Capri RS Owner

> GhostZ

01/21/2014 at 11:21 |

|

There is a lot of science, math, and calculations needed for a proper response to this post.

I have none of that. lol

I would, knowing your application shoot for one of the small block Fords, or the never dying impossible to kill Chevy 350 (which isn't on your list). While I have a 302Windsor, I am a huge fan of 351 Cleveland's for performance applications. That being said you can do some crazy stuff with 289 ford's and 351W's as well. For the crazy high RPM's I think the 289 might be your best bet if you're sticking strong to your list.

Your application doesn't necessarily need 600 hp so I would leave the heave big blocks behind, I think they'll wreck your weight distribution.

GhostZ

> MontegoMan562 is a Capri RS Owner

GhostZ

> MontegoMan562 is a Capri RS Owner

01/21/2014 at 11:30 |

|

Oh, how this on-paper project has evolved since I made this post...

The Chevy 350 got its own post where I toyed with making a 302 or LT1 327, both of which seemed like good options. They have the added benefit of being very cheap swaps (you can just buy a mounting kit and they connect to the 280Z's BW 5-speed, along with the Ford 302) and offer some added benefits. The biggest drawback of the 350 though is the rear-mounted distributor, which means that the engine (which is heavier than the stock one, though the ford is closer to stock) not only weighs more, but ALSO has to be mounted further forward than the Ford 302, which actually is a mid-engine setup if you custom fabricate mounts for it.

The 289's achilles heel is the lack of aftermarket cranks. A stock H.O. 289 crank would work for up to around 350HP, but I wouldn't want to push it to 500HP or more.

I think we've both shared the merits of the 351 in previous comments, but its crank journals won't fit a 289 or 302 crank.

The idea behind this build was to make a happy, high-revving V8 that would run for a little while longer, and then go forced induction on it if it can handle it.

Either way, agreed and recommended post.

MontegoMan562 is a Capri RS Owner

> GhostZ

MontegoMan562 is a Capri RS Owner

> GhostZ

01/21/2014 at 11:39 |

|

I realized that i stumbled upon the old old post hahahaha.

GhostZ

> MontegoMan562 is a Capri RS Owner

GhostZ

> MontegoMan562 is a Capri RS Owner

01/21/2014 at 11:39 |

|

The magic of notifications has allowed me to travel back in time to comment with you as well.